Autocad Mep 2013 Hangers Direct

Posted : admin On 03.01.2020Vault PromotionVaultCollaboration and data management softwareVault data management software helps organize, manage, and track data creation, simulation, and documentation processes for design, engineering, and construction teams. Get more control over design data with revision management capabilities and quickly find and reuse design data, for easier management of your design and engineering information.Vault PromotionNov 7, 2013 – Jan 24, 201430% off Vault Pro new seats with subscription or 20% off Vault Pro new seats without subscription. Offer limited to 10 seats per customer during the promotion.

Autodesk FabricationClick here to go toExtend the power of BIM and improve mechanical prefabrication processes with Autodesk® Fabrication. Autodesk Fabrication helps mechanical, electrical and plumbing (MEP) contractors enhance their workflows by adding powerful design, detailing, estimating and fabrication tools. Quickly move from a model into MEP fabrication or estimating with Autodesk® Fabrication. These impressive tools also allow you to use manufacturers’ specific information to help increase the speed and accuracy of your projects.

Read on to discover some of the benefits and features of Autodesk® Fabrication.Autodesk® Fabrication CADmep 2014Improve MEP design and detailing processes with Autodesk®Fabrication CADmep. Features:Shared content libraries and databases – Autodesk Fabrication products share libraries and databases, for more seamless workflows among estimating, detailing, fabrication and installation. Manufacturer-specific content – Fabrication CADmep uses libraries of real-world content so users know they are creating models that more clearly represent the final construction. Extend design-intent models with Revit import – Extend Building Information Modeling (BIM) downstream by using the Revit® import tool, and help reduce model redundancy. Design line drawing technology – Quickly develop MEP designs through to detailing by using underlays and design-line technology. Multiservice layout – Model several parallel services at the same time, helping reduce time spent on the model drawing process.

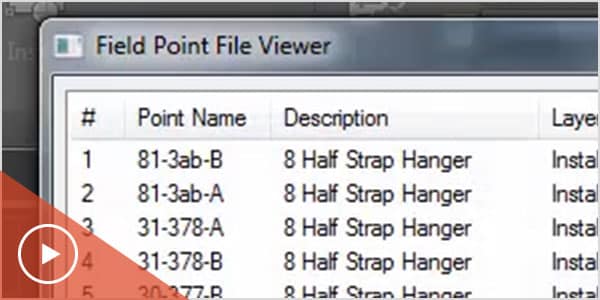

Multiservice hangers and sleeves – Add hangers and sleeves that span several services without the need for manual editing of sizes. 3D spooling capabilities – Easily create detailed spool sheets (or spool drawings) to support the prefabrication and modularization of MEP systems. PCF file preparation tool – More easily create isometric, or single line, spools for use in the fabrication shop.Autodesk® Fabrication ESTmep 2014Get a better understanding of MEP project costs with Autodesk® Fabrication ESTMep. Features:Shared content libraries and databases – Autodesk Fabrication products share libraries and databases for more seamless workflows among estimating, detailing, fabrication and installation.

Real-world content, pricing and costs – Access a library of real-world content, pricing, and costing data for more accurate cost estimation and analysis. Streamline bid creation with model import – Extend design-intent models from, or into Fabrication ESTmep for more accurate, competitive bids. Underlay trace takeoff – Quickly develop competitive bids using underlays and design line technology.

Comprehensive project factors – Create more accurate cost estimates based on project and market variables. Track project variations – Record all Adds and Omits on a job to support traceability and promote accountability for changes, and make comparisons against the original estimate. Value engineer – Perform value engineering on services more efficiently, and produce cost/benefit options for your clients.Autodesk® Fabrication CAMduct 2014Take advantage of comprehensive libraries and direct design to fabrication workflows with Autodesk® Fabrication CAMduct. Features:Shared content libraries and databases – Share libraries and databases for more seamless workflows among ductwork estimating, costing, detailing, fabrication, manufacturing and installation.

Comprehensive library of duct fabrication components – Access a large library of 3D parametric rectangular, round and oval ductwork components with associated developments. Sophisticated nesting options – Advanced nesting algorithms and options help deliver better material utilization.

Linear nesting for items and ancillaries – Gain a more accurate understanding of quantities needed for items that come from stock lengths. NC writing and machine support – With post-processors built in to support a variety of machine types, Fabrication CAMduct can help control your production line, whatever the size.

Job costing – Cost jobs based on a variety of project factors to better understand your bottom line. Autodesk® Fabrication CAMduct™ Components – Add input stations to help speed up output of components. Autodesk® Fabrication Tracker – Get status updates and barcoding to track the progress of components, plus real-time progress updates to improve the speed of client payment applications. Autodesk® Fabrication RemoteEntry™ - Provide remote access to your component database for clients to submit new jobs or deal with onsite change orders.Autodesk® 360 and Autodesk® BIM 360Share your work and communicate effectively with Autodesk® 360 and Autodesk® BIM 360. Features:Autodesk® 360 storage and job sharing – Store your jobs and database in the cloud using and more seamlessly share models and information with project stakeholders. Send to Autodesk BIM 360 Glue – Integration with adds enhanced model interrogation workflows for users. Which solution is right for you?

Contact CAD-1 today to discuss these powerful Fabrication tools and workflow enhancements! Autodesk® Fabrication CADmep 2014 Object EnablerWhen installed, this Autodesk® object enabler will allow you to access CADmep-created files in other Autodesk technologies, like Autodesk® Navisworks®.Download here:Click here to go to. Autodesk® Vault Professional 2014Collaboration and data management softwareVault data management software helps organize, manage, and track data creation, simulation, and documentation processes for design, engineering, and construction teams. Get more control over design data with revision management capabilities and quickly find and reuse design data, for easier management of your design and engineering information.Manage product and project dataVault data management software enables design and engineering teams to collaborate on better designs with fewer errors and automates the product or project lifecycle. Features facilitate collaboration, data search and reuse, and revision management to help manufacturers, engineers, architects, and contractors make better use of their design data.Features Include:Data Management Fundamentals.

Automated data management. Best-in-class CAD integration. Central location for project dataProduct Data Management for Manufacturing. Automated engineering change orders. Business system integration. Revision controlProject Collaboration for AEC.

Connect to the cloud with Autodesk Buzzsaw.

Autocad Mep 2013 Hangers Direct Free

Joel LondenbergAuthor: Joel Londenberg is a BIM consultant using Revit MEP to support the entire building industry from as-built laser scanning and model creation to multi-discipline engineering, BIM coordination, fabrication, shop drawings, and field layout. With more than 20 years experience in 3D modeling, Joel has a wide perspective of the MEP workflow in our industry.

Engineers, manufacturers and contractors alike have benefited from his diverse exposure through in-house training, content creation and 3D modeling services. Visit www.bimbox.biz for more information. August 25th, 2016 Fabrication for Revit MEP - 5 Years InThis is a follow-up to the article with the similar title published a year ago. It’s always been one of my favorite things about Autodesk® Revit® MEP—that the developers really are working on improving our experience with each release. The Fabrication feature set in Revit 2017 is an example of that continuous incremental improvement.

If you’re especially curious, you can find that previous article in June 2015 AUGIWorld.We Revit users spend most of our efforts digitally, generating content for models and drawings, reviewing PDFs, responding to RFIs. After putting so much effort into the digital version of a building, I don’t know any designer who is happy with the idea that the builders and fabricators just set aside these drawings and start over. We all want to see a more direct translation of our effort into the actual building components.In October 2011 Autodesk announced the purchase of MAP Software, taking a big stride toward that goal of direct translation to fabrication data. However, much of my previous review was spent pointing out how far they still needed to go.Here is the short list of functionality that I still expect in order to consider the fabrication features complete inside of Revit:. Maintaining the Revit style of modeling. Full engineering support. The same ease of documentation.

The ability to create a complete model. Spool drawings. Direct export to fabrication equipment. Support for robotic field layoutJust as before, this is my personal review of the fabrication software within Revit.

Revit’s Style of ModelingThere are some nice improvements and additions, which I’ll cover at the end of this section, but I’ll start with the default and most obvious method presented by the user interface. As you can see from the many available demo videos of the new fabrication features in Revit 2017 (for example or Autodesk’s own channel ), fabrication parts are not modeled in Revit in the same fashion as standard MEP elements. The modeling method for standard Revit MEP elements is strongly based on the straights, allowing the system family settings to insert transitions and bends for you. The new fabrication features default to specifically picking and placing all components. As I said, this is not the only way, just the most obvious.For instance, here is the process to create a run of duct (aligned to another run) 15 feet long, reduce its size, run 3 more feet, turn and run another 15 feet.